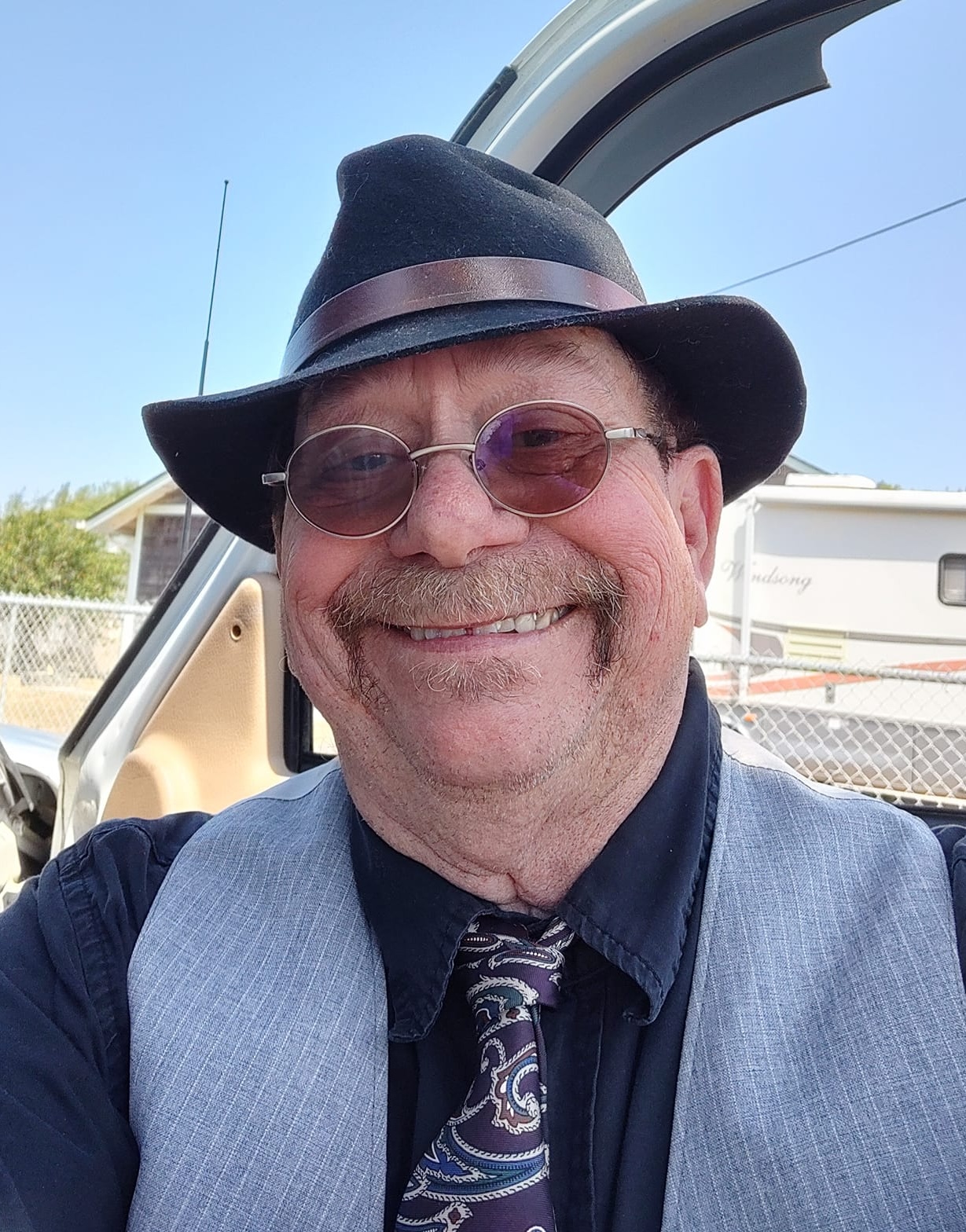

Guest Column: My three hack saws

Published 5:00 pm Tuesday, October 25, 2005

I own three hack saws. Considering I have only used a hack saw twice in the past 40 years that’s probably too many.

My dad bought me my first saw along with a well-stocked tool chest when I left for college. He had high hopes of me getting a good education, avoiding the Vietnam War, and learning how to use the tools. Two out of three ain’t bad.

About 20 years ago we had a hard freeze here at the beach and I needed a hack saw to cut through the broken copper pipe beneath our house. I couldn’t find the saw dad gave me so I bought one, did the necessary repairs, and went to put away the saw. When I opened the closet naturally I found my other hack saw.

Last month I again was in need of a hack saw, this time to cut through a 12-inch anchor for the new beams that would support our upstairs bathroom and second story. No hack saw was to be found, so I bought the third one, one with a pretty yellow handle and blade advertised as carbide steel. You guessed it, when I went to store it I found the first two.

The beams were part of a giant improvement project my wife, a friend, and I had decided to undertake. Well mostly she told me to undertake and my friend unwittingly agreed to help. Besides the beams, we replaced a deck that was showing serious signs of dry rot after 25 years and did some finish work inside. The deck is 14 feet above the ground and goes for 60 feet. Having vertigo can be a very serious disorder but it also got me a steady job of holding ladders and handing boards up to my less vertically challenged co-workers.

The problem is that 4×12’s are heavy and that most of the boards had to be cut. The chop saw was great, but what’s the difference between 47 9/16 and 49 7/16 inches? I mean who really cares? Obviously my wife and friend cared because I often cut expensive treated boards two and three times and they were still too short. Fortunately we had enough need for wood that eventually everything was used somewhere.

I’m the kind of guy who “eye-balls” things rather than measure. I’ve learned that the way I use a tape measure just guessing is more accurate. Besides, how come the little clip on the end of a tape never quite stays caught on what I’m measuring unless it gets hopelessly stuck in a groove five inches above my reach. And then the tape either retracts when you don’t want it to or won’t reel in when it should. At least I have five of them now as I temporarily lost the first four. I like the green tape measure the best.

Being the “ground man” I also had the dubious duty of going to the lumber yard to buy whatever we needed. So was that sixteen 2×6’s 12 feet long or six 2×12’s 16 feet long or . . . ? Pine or oak? Screws or nails? Galvanized or brass? Then there was the problem of carrying half a dozen 16-foot pieces of lumber in a pickup with a six-foot bed. The knots I used to tie the lumber down were either too loose or such that I couldn’t get them undone, but luckily nothing really bad happened between the lumber yard and my place. Unless you count scratching my pickup’s paint as bad.

One time I actually got on a step ladder and used a knife, chisel, hammer, pliers, screw driver, and carpenter’s square pencil to cut out a place for an outside light to be inset in the shingles we had put on the south side of our home. I quickly turned a 15-minute job into two hours, but I got the receptacle in place only to find that I had plugged the halogen lights into the wrong holes. After some prong-bending and a flashlight I was able with the help of my wife to triumphantly say, “Let there be light, and there was.” And I did all this on the second step of the ladder.

I had turned off the electricity for the second time when I discovered I had plugged in the bulbs incorrectly so I then proceeded to again set two dozen digital clocks, VCR’s, stereos, stoves, TV’s, and microwaves in our house that were all flashing 12:00! Too bad there isn’t vertigo for electrical things, too.

After nearly three weeks we were nearing the end of our five-day deck-building project by putting on the railings. I got my calculator, measuring tape (four feet spans are too hard to eyeball), and a round pencil and began to figure out width we needed between rails.

The evening before I had cut 204 spindles, 203 of which were near perfect. I also calculated that was a 99.5 percent rate of accuracy, not bad for a guy with vertigo and in his rookie year on a chop saw.

My friend, who had used the patience of Job and the Wisdom of Solomon throughout the project, suggested using the chop saw on the final piece of treated wood. When I asked him if he remembered where I put the hack saws his countenance changed to that of a young Charles Manson. It may not have helped that my wife was asking him if we could help in creating a chandelier in the shape of a wagon wheel.

The way I figure it, if you have good tools you should learn to use them.